A Closer Look at Lathes and Milling Machines

At T Shinton Engineering Ltd, we have a range of both lathes and milling machines that we use regularly in our work. Since 1977, we’ve been carrying out a wide range of engineering and reverse engineering services for customers across Wolverhampton and beyond. Our team of friendly engineers are able to carry out a range of engineering services, including milling and turning, keywaying, boring, sub-contracting, surface grinding, gear manufacturing, industrial machine repairs and more. We only use the highest quality materials for all of our work and use state of the art equipment which means our expert engineers are able to create component parts that are second to none and we’re the number one choice in Wolverhampton because of this.

What’s the Difference Between Lathes and Milling Machines?

Lathes and milling machines are similar in that they can both be used for cutting raw materials, but each has very different ways of doing so. This is why it’s crucial to know the difference between the two, the materials they are best used on and the different finishes they’ll produce. That’s why it’s important that they’re used by knowledgeable, experienced and qualified people, such as our team members here at T Shinton Engineering Ltd.

Lathes work by spinning the raw material in order to cut it while the actual cutting tools themselves stay fixed. Lathes create cylindrical parts using outside and inside diameter cutting tools of different shapes and sizes. The material to be cut and shaped spins on a chuck while a specialist tool cuts away materials to create the desired shape. Lathes use insert cutters, which use a removable tip that cuts and shapes the raw material which is spinning in the chuck jaws. This type of cutting tool is not used on a milling machine and can produce very different results.

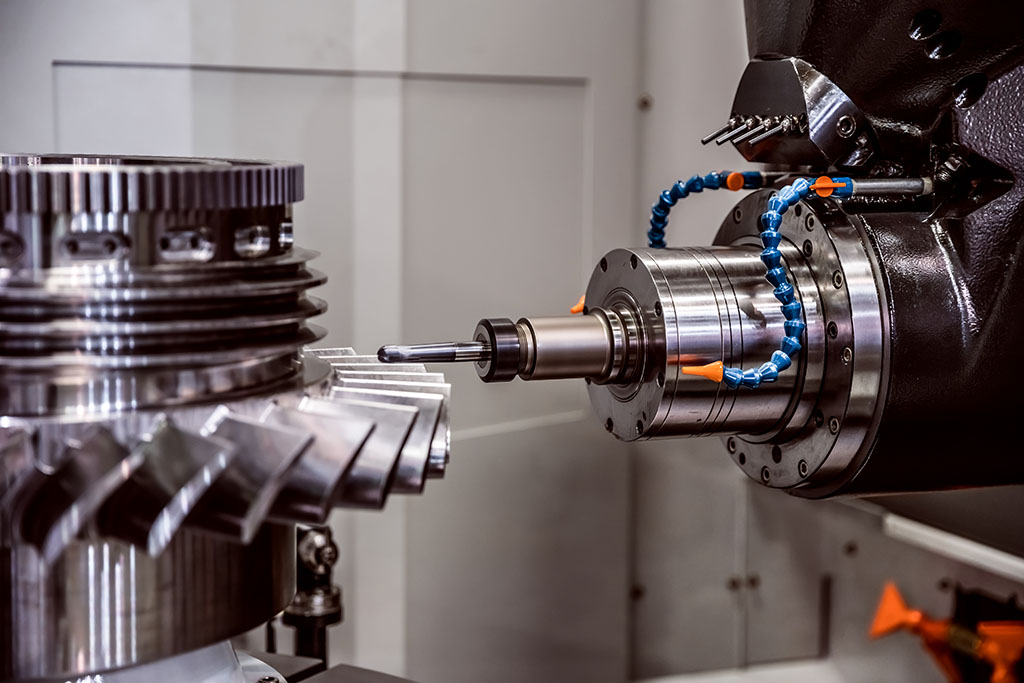

Milling machines are different in that they use a spinning tool for various different cutting operations. Milling machines hold the material to be cut while the tool that cuts it spins and the cutting tools used on milling machines are cylindrical. The most commonly used type of cutting tool on a mill is the end mill. This is placed on the spindle and spins at various speeds based on the type of material being cut.

Speedy Delivery When it’s Urgent

For any of our customers who urgently require replacement parts in a hurry, we always do our very best to accommodate. We are normally able to offer same day delivery services using our own personal transport within just 24 hours.

We also have a range of engineering products available. This includes crank shafts, flywheels, bushes, lathes, millers, bore gauges, carbide bits, centre drills, gears, drilling machines, screw cutting, lathe, milling and threading tools and micrometres and cutting tools.

If you’d like to learn more about our services, we’d love to hear from you. Give our friendly team a call on 01902 402 266 or 01902 497 777 or email tshinton.rich@gmail.com.

Review Us!

Review Us!